AUTOMATIC MACHINES AND WORKING FINISHING LINES

FOR PROFILES WOOD-MDF-PVC-POLYSTYRENE

![]()

PAO MACC GROUP MANUFACTURER ,UPON REQUEST, MANY SPECIAL MACHINES

HERE YOU CAN FIND SOME EXAMPLES. IN ANY CASE DON'T HESITATE TO CONTACT US FOR SPECIAL AND/OR DIFFERENT APPLICATION

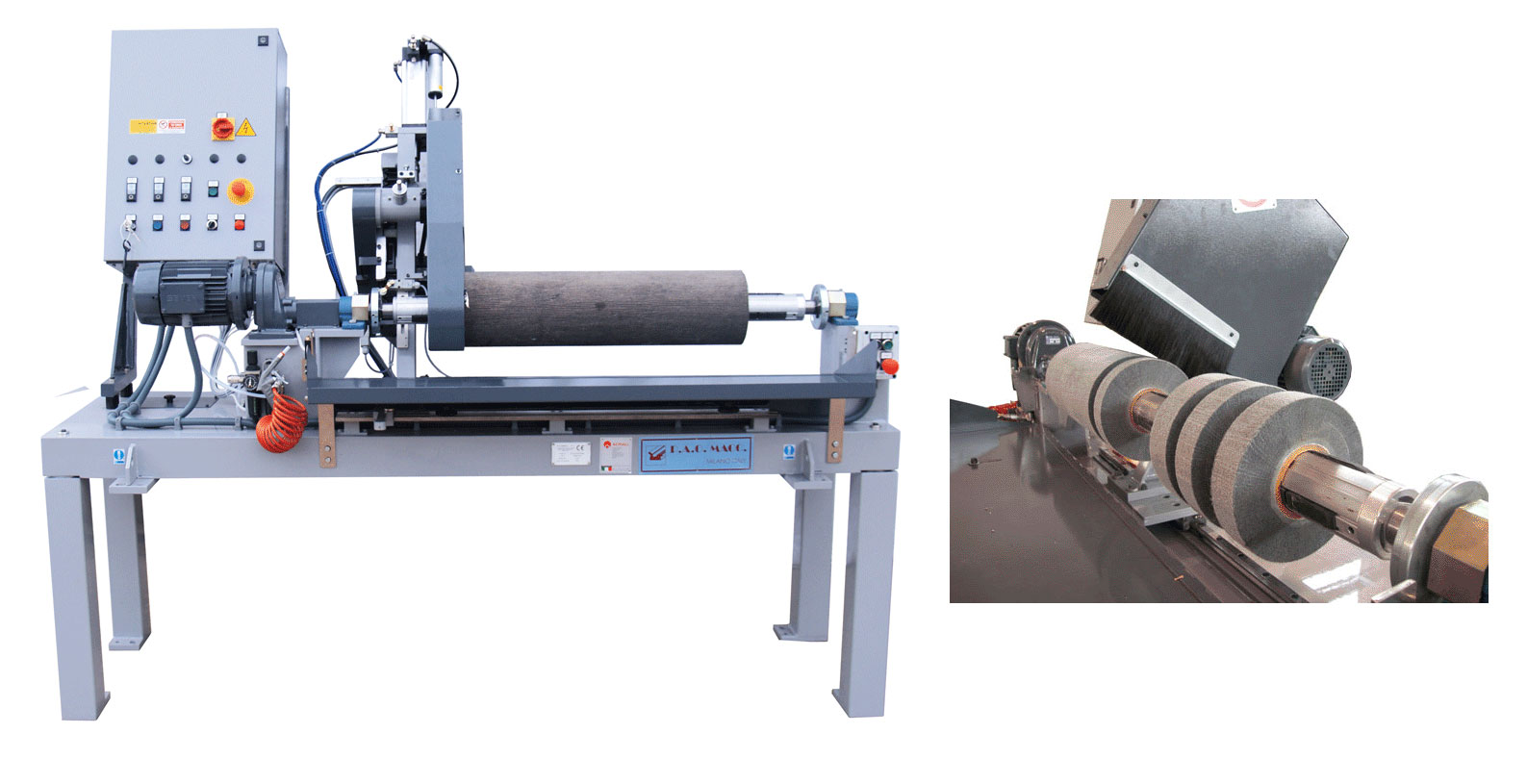

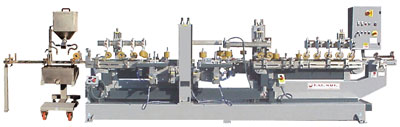

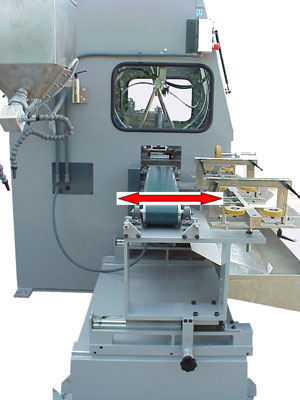

SANDING WHEELS SLICER MACHINE

FOR NORMAL PRODUCTION

FOR 1000 X 200 mm. JUMBO ROLLS

With this machine is possible slicer all kinds of abrasives sanding wheels from a normal 1 Mt. Jumbo roll. The machine is built with a very solid steel base and very accurate rectified horizontal and vertical ‘T’ tempered slides and two turrets. Booth, of its, support a motor unit with a pneumatic/expandable and auto-Centering spindle. The motor and the spindle are operate and governed by a Siemens Inverter. Over the two turrets is positioned the 3” spindle pneumatically expandable where the jumbo roll is hook. The horizontal displacement in according with the width of the wheel is manual moving. The blade is diamond type . The slice operation is completely automatic through a pneumatic cylinder; the cutting speed is adjustable by an hydraulic brake. The machine required a good suction unit device. (reccomended )

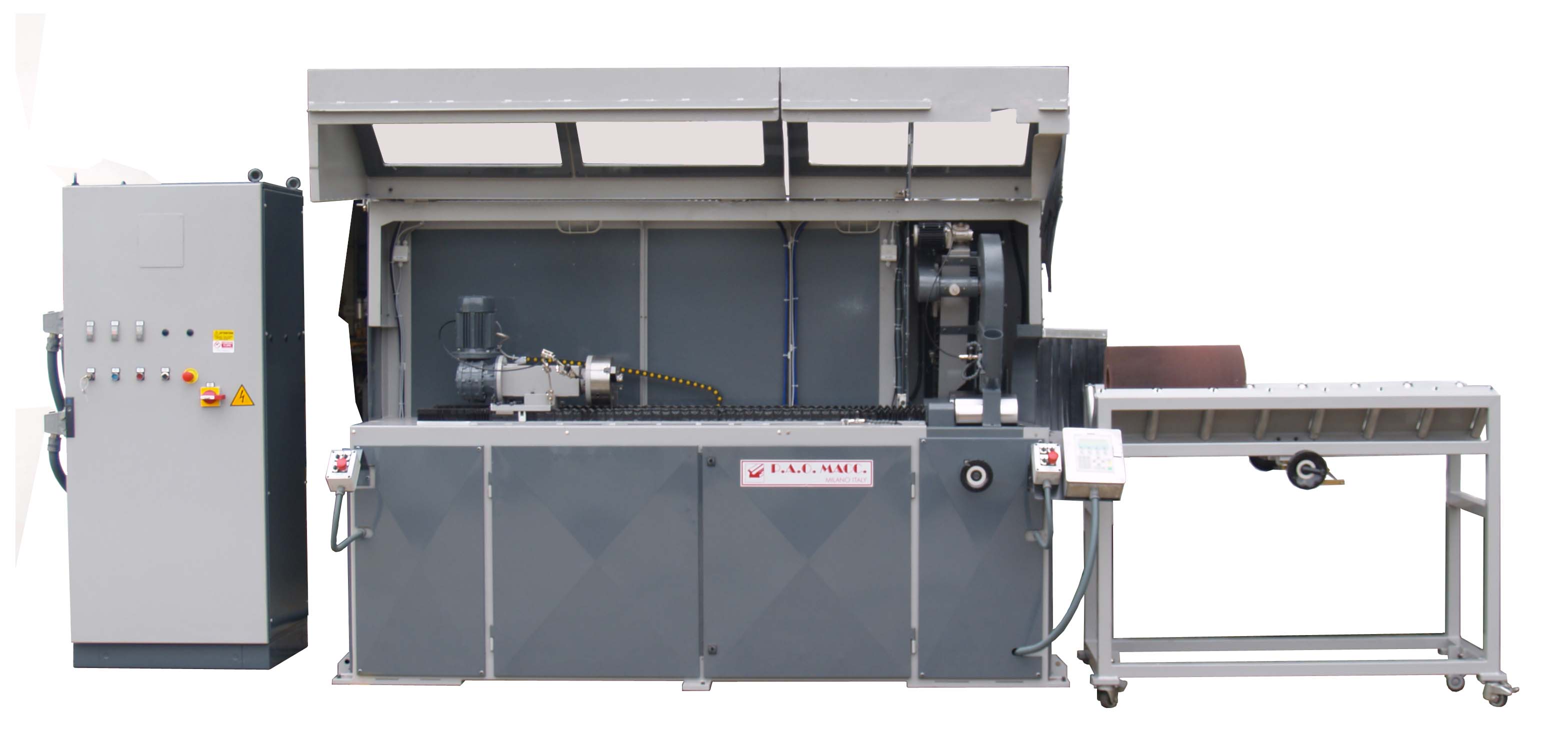

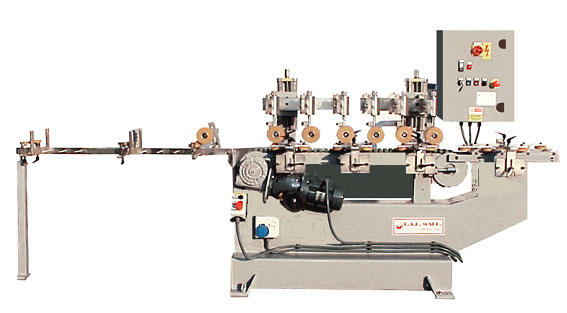

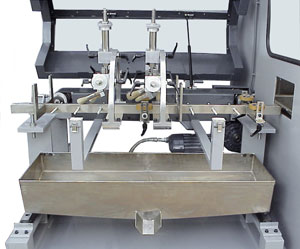

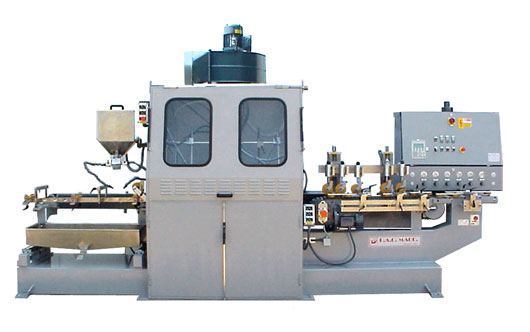

SUPER AUTOMATIC SANDING WHEELS SLICER MACHINE

FOR HIGH PRODUCTION

With this machine is possible slicer all kinds of abrasives sanding wheels from a 1,5 Mt. Jumboroll. The machine is built with a very solid steel base and very accurate rectified horizontal and vertical ‘T’ tempered slides .All the working operations of the machine are automatic and are control by a PLC Siemens.The jumbo abrasive roll are supported in both side : on the left by an adjustable spindle and on the opposite side by two rollers with external speed synchronize with the jumbo revolution.The spindle are moving automatically by a special motor that provide the right horizontal movement in according with the PLC instructions loaded.The Blade motor unit is mounted on a very strong support; and by a tangential movement provides to obtain a perfect slicer cutting; this movement are made by a special motor even controlled by the PLC.The blade is diamond type.The slice operation is completely automatic. The machine required a good suction unit device ( recomended ).

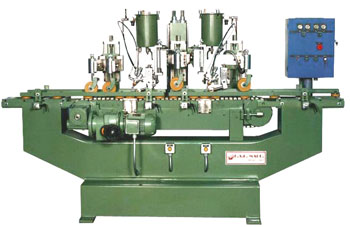

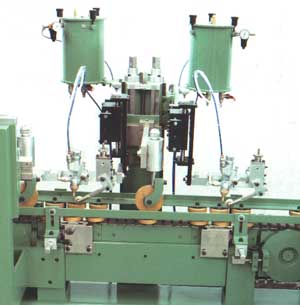

AUTOMATIC STRIPE LINE MACHINE

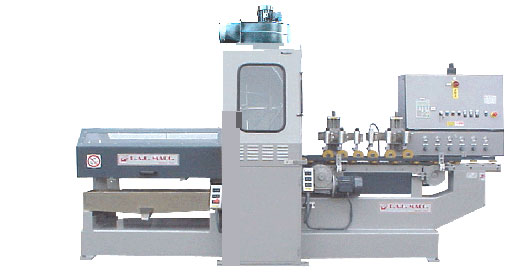

WORN AND AUTOMATIC OLD EFFECT MAKING MACHINES WITH

WAX WIPING MACHINES

The machine is built with a solid structure of steel plate and tubular elements, electrically welded together to provide a high degree of solidity and stability. Specialized Machine designed for create inimitable old effect on wood profiles of pictures frame moulding.

With this machine it is also possible to add and wiping profiles with cold or/and hot wax , by interchangeable trolleys.

In the end of the machine , On the wiping tunnel position, instead of wax trolley , is also possible to install a gas-air blowpipe to burn and create very special effects.

( gas-blowpipe not supplied from PAO MACC )

Moulding is transferred by a positive system of a caterpillar-type belt comprising 1/2” thick rubber, 7/8” wide 4,5” long links and top and bottom rollers to ensure consistent stability in material transfer.

GENERAL FEATURES FOR A MACHINE WITH 4 HEADS AND FINAL WIPING TUNNEL:

Length 6.080 mm.

Width 1.400 mm.

Height 1.800 mm.

Weight 2.050 mm.

Installed Power Kw. 2.0

Total Motor Power Kw. 1,1

Compressed Air pressure 3 BAR

Air Requirement 40/Nl. SCFM 1,4

Working Level 870 mm.

WAX WIPING MACHINES

The following are the details regarding the most used model :

GENERAL DESCRIPTION

The machine is built with a solid structure of steel plate and tubular elements, electrically welded together to provide a high degree of solidity and stability. Composition of the machine:

1- In-feed Conveyor chain with side guides and sprung upper guide pulleys

2- An support as final tunnel for wax wiping

3- Interchangeable trolley for Wax

DESCRIPTIONS OF THE OPERATING UNITS

1 st.

Double 5/8” neutral Para rubber, 110 mm wide chain drive for initial / final thrust. The feed speed is adjustable through a 2 Hp variator , from 9 to 45 Mt/minute. Sprung upper guide pulleys with rubber wheels with bearing for the stability of the moulding. Guides with rubber wheels ( Dia. 70 x 15 mm. ) and bearing. Vernier scale on the left side of the machine for perfect alignment of the guides.

2 nd.

Final section for wax lay off ( wiping tunnel ). It consists of an horizontal support with side guides for the side wheels not to damage the previously accomplished process. The support is fit for assembling of a rubber sponge wrapping system on the profile ( or industrial cotton-waste ) or/and six paint brushes mounted on two arches . This final section of 1,4 Mt. length enables one or two operators to carry out manual operations such as lay off of the wax and varnish

3 rd.

Interchangeable trolley with wheels and hot and/or cold wax Stanley steel container.

The container is provided with two special tillable tube; its depose the wax over the profile and the wiping tunnel made uniform quantity.

TECHNICAL DATA : C0MPLETE MACHINE WITH ONE TROLLEY

LENGTH : 3.550 mm. With final tunnel included

WIDTH : 1.500 mm.

HEIGHT : 2.000 mm.

WEIGHT: 600 KG. + 70 Kg. Each Wax Trolleys

Installed power : KW. 4,00

Conveyor motor power : KW. 0,75

Working speed : 15-75 Mt/min.

Working Level : 870 mm.

TECHNICAL DATA : ONLY TROLLEY

LENGTH : 500 mm.

WIDTH : 750 mm.

HEIGHT : 1.650 mm.

WEIGHT : 83 KG.

Installed power : KW. 1,00

Working Level : 870 mm.

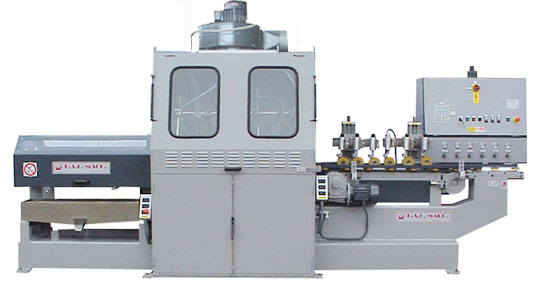

AUTOMATIC SPRAY-PATINA COMBI MACHINES

AUTOMATIC COMBI SPRAY PATINA MACHINE - PA3C/1

General descriptions of the machine

The machine is built with a solid structure of high quality steel plate and tubular elements, electrically welded together to provide a high degree of solidity and stability. The machine has 3- 4 OR 6 ( OR more ) automatic spraying guns and one or two separate station inside of the spray booth. The machine includes a SIEMENS PLC to operate automatically the activation of the guns in relation to the conveyor speed. The computer counts the number of pieces and the total number of meters that have been processed as well as the time in minutes required for the execution of any one operation. The mouldings are transported by two separate system :

-The 1 st . in-feed of the machine by means of caterpillar double 5/8” chain rubber covered 110 mm. Wide.

-The 2 nd . , out-feed of the machine, by means a 120-mm wide solvent-resistant belt and/or, thought a removable device , an flat steel base for final wiping tunnel support.

Booth system aren't connected with mechanical joint but each part has it own motor, with inverter, in electrical axis, so the speed are perfect synchronized with only one speed control device.

On the in feed caterpillar chain belt are possible to positioned arches with peeling heads, for scratching operations. The operating speed can be adjusted from 20 to 80 meters/minute . Between the two transports it is positioned an spraying booth station ; It can be rapidly opened so the guns can be easily reached. The recovery tanks can be cleaned easily as they can be completely removed. The back side of the booth has a 1 or more removable drawer for inserting a filter ( wood shavings) and it also has an electric exhaust fan with a rating of 4.000/8,000 cubic meters/hour. The guns are fed by a twin-membrane pump drawing directly from the paint drum.; upon request is possible also have two or three upper paint tanks for use different colours in the same time. Control of the atomisation air is independent for each individual gun. All guns can be operated automatically by means of a limit switch on the vertical presser. On the final tunnel device support is possible to positioning one or two arches with painting brushes for special furnishings.

PA3C/1-PATINA SPRAY MACHINE 1 STATIONS 3 or 4 GUNS

LENGTH : 4.250 mm. WIDTH : 1.400 mm.

HEIGHT : 2.600 mm. WEIGHT: 1.550

Installed power : kW. 6

Guns Number : 3 or 4

Compressed air pressure : 6 Bar (90 PSI)

Air requirements for Guns : Nl/Max.2.000 - SCFM 70,7

Air requirement for Blowers : Nl/Max. 2.000 - SCFM 70,7

Working speed : 10-90 Mt/min. - 33/270 Ft/Min

Working Level : 870 mm

AUTOMATIC COMBI SPRAY PATINA MACHINE - PA6C/2

WITH INITIAL TRANSPORT WITH 5/8” CHAIN RUBBER CATERPILLAR - 6 GUNS SPRAY BOOTH - FINAL WIPING TUNNEL

PA6C/2 - SPRAY PATINA MACHINE 2 STATIONS 6 GUNS

LENGTH : 4.750 mm. WIDTH : 1.400 mm.

HEIGHT : 2.600 mm. WEIGHT : 1.800 Kg.

Installed power : kW. 6

Guns Number : 4 or 6

Compressed air pressure : 6 Bar (90 PSI)

Air requirements for Guns : Nl/Max.3.000 - SCFM 106

Air requirement for Blowers : Nl/Max. 2.000 - SCFM 70,7

Working speed : 10-90 Mt/min. - 33/270 Ft/Min

Working Level : 870 mm.

INTERCHANGEABLE BELT AND/OR FINAL WIPING TUNNEL

WIPING TUNNEL WITH ARCHES AND ADJUSTABLE BRUSHES

AUTOMATIC COMBI SPRAY PATINA MACHINE WITH WAX CONTAINER AND WIPING TUNNEL - PA6CW/2 MODEL

SPECIAL HOT STAMPING FOIL MACHINES

HOT STAMPING FOIL FOR HEADS FURNITURE PROFILES

HOT STAMPING FOIL MACHINES FOR SPECIAL SHAPED BORDER - EDGES CONTOUR etc..

SEMI-AUTOMATIC MACHINE

ASK FOR OUR COMPLETE CD MULTIMEDIA PRESENTATION

Copyright(c) 2009 -

paomacc group -

info@paomacc.net